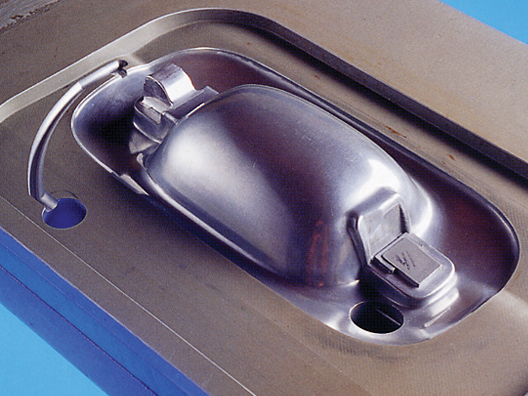

Aluminum-Filled High Temperature Resins

Aluminum-filled epoxy casting resins (dark gray in color) are not as heavy as iron-filled systems, are more readily machinable, and are available with higher temperature resistances..

Epoxy casting resins generate heat (exotherm) during the curing process. This heat can become excessive if the epoxy is poured thicker than the suggested casting thickness, causing warping, cracking and/or brittleness. Therefore, be careful to choose the correct system to pour your part.

Epoxy casting resins generate heat (exotherm) during the curing process. This heat can become excessive if the epoxy is poured thicker than the suggested casting thickness, causing warping, cracking and/or brittleness. Therefore, be careful to choose the correct system to pour your part.

Freeman 850/50 High-Temperature Epoxy Casting System

89D Shore Hardness / 1" Cast Thickness / 45 Min. Gel Time

Freeman 850/51 High-Temperature Epoxy Casting System

89D Shore Hardness / 4" Cast Thickness / 200 Min. Gel Time

Freeman 925 High-Temperature Epoxy Casting Resin

90D Shore Hardness / 1" Cast Thickness / 37 Min. Gel Time

Sika EC-415 High-Temperature Epoxy Casting System New!

88-90D Shore Hardness / 3" Cast Thickness / 90-180 Min. Gel Time

Sika EC-433 High-Temperature Epoxy Casting System New!

90-91D Shore Hardness / <1"-3" Cast Thickness / 120-270 Min. Gel Time