Liquid Tooling Materials

Fast-Cast Polyurethanes

Fast, low cost, filled urethane systems for foundry tooling, molds, prototypes, and models.

Polyurethane Elastomers

Extensive line offering a wide range of working times, demold times, hardnesses, and performance characteristics.

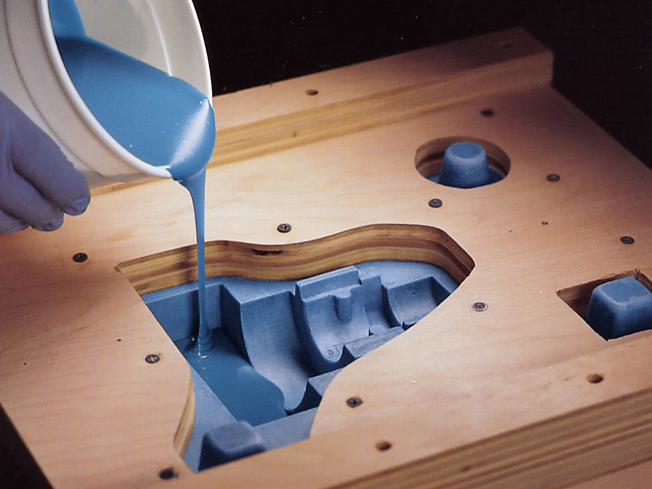

Silicone Rubber

Extensive line of flexible silicone materials and accessories.

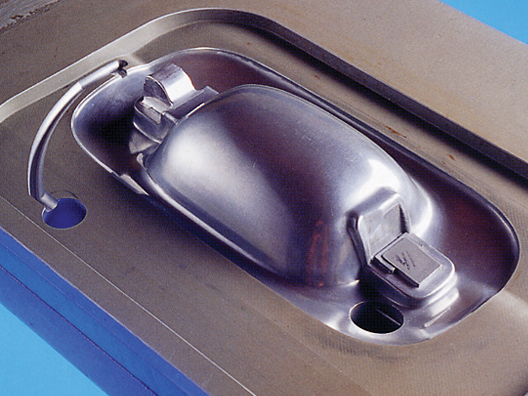

Epoxy Casting Resins

Aluminum and iron filled casting systems for creating foundry patterns, core boxes, fixtures, molds and tooling.

Epoxy Surface Coats

Wide range of epoxy surface coats for creating general purpose, abrasion resistant or heat resistant laminated tools.

Epoxy Laminating Resins

A variety of epoxy laminating resins for constructing fiberglass laminated tooling.

Epoxy Aerospace Syntactics

Epocast® aerospace syntactics for reinforcing honeycomb panels and cores.

Specialty Tooling Pastes & Resin Systems

Paste compounds for tool construction and alteration, often used as a reinforcement behind surface coats.

Resin Infusion Epoxy Systems

Developed to meet the needs of composite manufacturers involved in vacuum assisted resin transfer molding systems.

Polyester Resins & Gelcoats

General purpose polyester resin, gelcoats, & catalysts used to construct laminated molds & parts.

Dyes, Pigments, and Additives

Epoxy, urethane, and polyester dyes, pigments, epoxy diluents, and resin additives.

Tooling Plastics Fillers

Aluminum fillers, ceramic spheres, and other fillers used in liquid tooling applications

Plasters, Gypsum Cements & Accessories

Extensive line of casting plasters and gypsum cements.