Machinable Media Selection Guide

Use this guide to follow the history of constructing parts, patterns, tools, and molds from lumber and metal into the synthetic materials we use today, and the criteria to use to select material for your project.

The Process

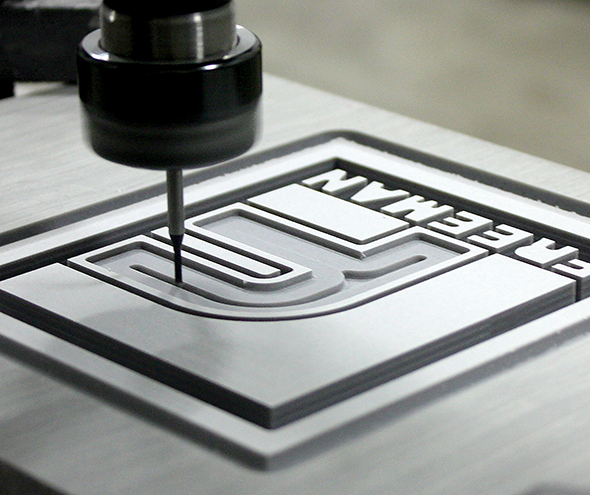

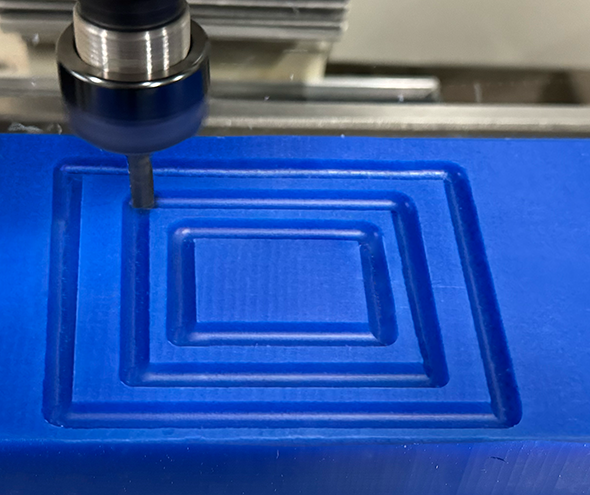

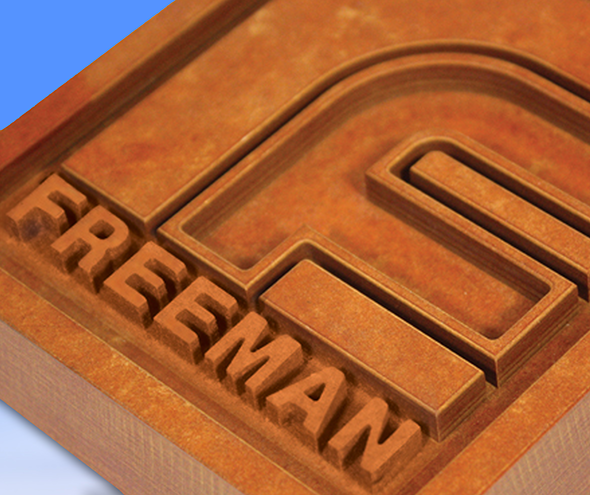

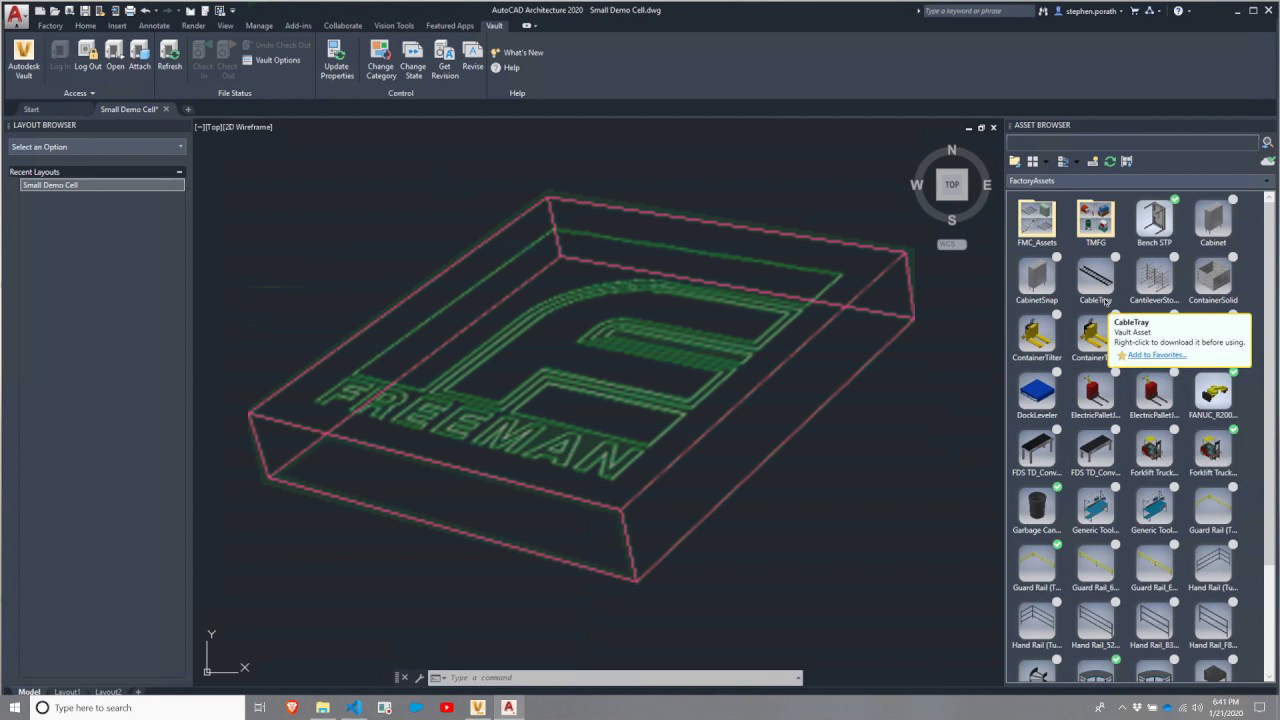

The prototyping process begins with a design which can then be machined into a part, pattern, tool, or mold for additional testing or use. | ||

|

|  |

|

Design Stage |

Completed Part, Pattern, Tool, or Mold | |

The Journey to Synthetic Materials

Historically, when constructing parts, only two materials were commonly used. Wood is inexpensive, easily workable, moderately stable and durable, but the presence of grain can create machining issues. Metal is very stable and durable with a superior machined finish, but is much more expensive.

Wood  | Metal  |

Less Expensive | More Expensive |

With these choices being so extreme in differences, recently developed synthetic materials have bridged the gap, offering a wider range of materials to choose from.

Rough Lumber  |

MDF  |

Perfect Plank  |

Foam Boards  |

Machinable Wax  |

Modeling Boards  |

Tooling Boards  |

Phenolic Richlite  |

Epoxy Boards  |

Metal  |

Less Expensive | More Expensive |

Material Selection

The product information below should be considered guidelines and not rules. The best material for your application will vary depending on the unique characteristics or criteria of your project, such as:

|

|

Premium Synthetic Materials

Freeman Modeling

& Styling Boards

Freeman Tooling

& Hi-Temp Boards

Freeman

Machinable Wax

Economical Synthetic Materials

Polyurethane

Foam Boards

MDF (Medium

Density Fiberboard)

Lumber Products

Perfect Plank

Engineered Wood

Rough Sawn

Lumber

| Still need help selecting material for your project?Reach out to our tech team by email or phone at (800) 321-8511 opt. 3. |